Laser Welding Machine Welding ngesandla

Inkcazo:

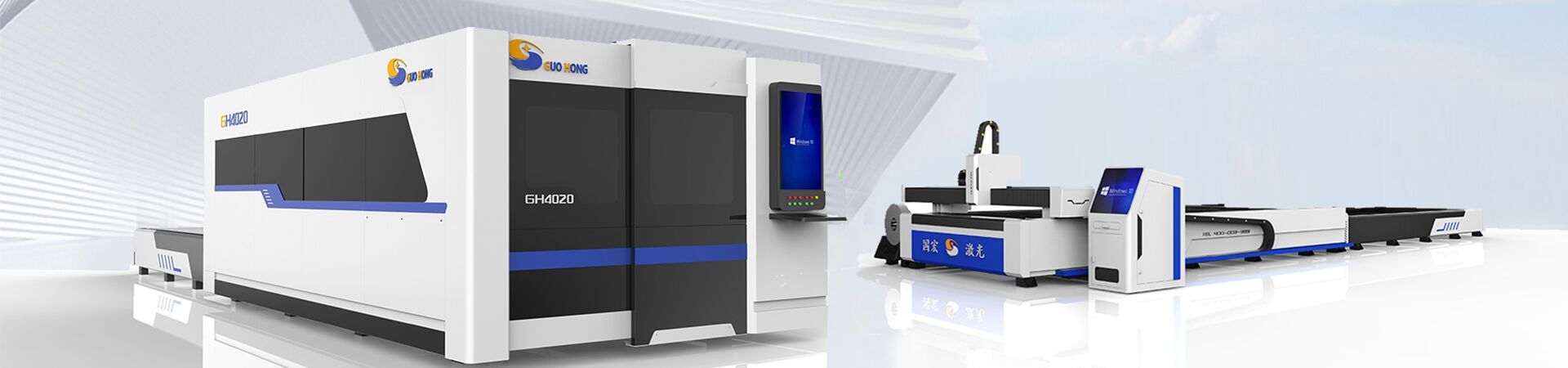

Umatshini iwelding laser ngesandla

Flexible and Convenient, Weld kwiNtando

Umatshini we-laser we-laser ophethe ngesandla usebenzisa isizukulwane samva nje se-fiber laser kwaye ixhotywe ngentloko ekrelekrele ye-laser.Ineenzuzo ezininzi ezinje ngokusebenza okulula, umgca wokuwelda omhle, isantya se-welding esheshayo kwaye akukho zixhobo ziphelayo. Izicelo ze-Welding kwizinto zesinyithi ezinje ngeepleyiti zentsimbi ezingenacici, iipleyiti zecarbon zentsimbi, kunye neemakhishithi ezenziwe ngesinyithi zingabuyisela ngokuchanekileyo iwelding arc kunye nokuwelda ngombane. Umatshini ophethe i-laser welding unokusetyenziswa ngokubanzi kwiikhabhathi zasekhitshini, izinyusi, izishelufu, iioveni, ucango lwesinyithi kunye neefestile zewindows, iibhokisi zokuhambisa, ikhaya lesinyithi kunye namanye amashishini.

Flexible and Convenient, Weld kwiNtando

Intloko ye-laser ephathekayo ephathekayo, ukukhanya kunye nokuguquguquka, inokuyinyusa nayiphi na indawo yomsebenzi. I-Welder ayizukuziva idiniwe emva kokusebenza ixesha elide.

Ukuhamba rhoqo kwe-welding head welding

Imilo engasindi, indlela yoyilo lobunjineli bomzimba, ukubambelela kakuhle; Isandla esinye kulula ukusilawula, kulula ukusebenza.

Ngee-alamu zokhuseleko ezininzi, ukukhanya okuzenzekelayo kokutshixa emva kokuhamba kwezinto, ukhuseleko oluphezulu.

I-weld entle, isantya esikhawulezayo, akukho zinto zisetyenziswayo, akukho phawu le-welding, akukho mbala, akukho sidingo sokupholisha kamva.

Unokuqwalaselwa ngeendlela ezahlukeneyo zomlomo we-Angle ukuhlangabezana neemfuno ze-welding zeemveliso ezahlukeneyo.

Icwecwe kwaye kulula ukuHamba

IPARAMETER

| Umzekelo | GH-SC-500W / 750W / 1000W / 1500W | ||

| Ubungakanani beLaser | 1.06um | ||

| Laser welding ubunzulu | 0.1-5mm | ||

| Ububanzi Pulse | 0.1-10ms | ||

| Indlela yokusebenza | Iyaqhubeka | ||

| Iimfuno zamandla | 220V / 50Hz-380V / 50Hz | ||

Isampuli yeWelding

Iimbonakalo:

Ubuncinci besayizi, ubhetyebhetye kwaye ulungele

Hlanganisa i-laser, itanki yamanzi, kunye neendawo zokulawula kunye, ubungakanani obuncinci, iimfuno eziphantsi kwindawo yokusebenza. Iifayile ezihambisekayo zenza ukuba indawo yokusebenzela ibe lula xa kufuneka njalo. Umpu wokuwelda ophethe ngesandla uxhotyiswe nge-5m, 8m okanye i-10m ifayibha ebonakalayo, eqhekeza ngokusikelwa umda kwibhentshi yomsebenzi, isenza uluhlu lokudibanisa lubanzi kwaye lujongane neentsimbi ezahlukeneyo. Inokudibanisa nayiphi na indawo yomsebenzi kunye nekona oyifunayo.

Umgangatho ophezulu we-welding, i-welds eqinile

I-laser eqhubekayo, ukutshintsha kwe-weld egudileyo, ii-welds eziqinileyo, akukho sikali seentlanzi; Ukuchaphazeleka kancinci kukufudumala kwe-welding, indawo encinci etyheli kunye nendawo emnyama kumacala omabini ee-welds, i-workpiece deformation; Umphezulu welding Smooth, akukho mfuneko yokuba wokucoca ngakumbi, ukonga zabasebenzi kunye neendleko ixesha.

Ukusetyenziswa okuphantsi kunye neendleko zokugcina

Ireyithi yokuguqula umbane we-laser eqhubekayo iphezulu ngaphezu kwe-30%, ephindaphindwe kalishumi kunaleyo ye-YAG laser (3%), kunye nozinzo lwamandla ± 0.5%; Akukho lens ebonakalayo kumngxunya we-resonant, kwaye umthombo wempompo unokuhlala ngaphezulu kweeyure ezingama-100,000, ngaphandle kwesondlo; Akukho sidingo sokongeza ucingo lwe-welding ngexesha le-welding, kwaye akukho zindleko zongezelelweyo zongezelelweyo.